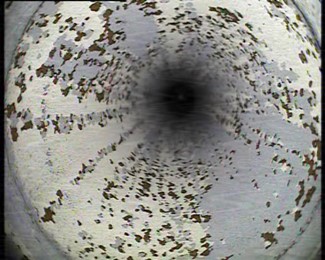

The Thorp Medium Active Salt Free Evaporator (MASFE) requires its evaporator tubes to be cleaned to enable a thorough inspection of the tubes to take place. Shepley Decontamination Services were contracted by Sellafield Ltd to high pressure water jet clean the internal bores of the evaporator tubes. This was to allow for the detailed inspection of the tubes to take place and also extend the operational life of the evaporator.

Cleaning of the evaporator tube internals removed deposits that had built up during past operations.

Selective inspections were undertaken both before and after water jet cleaning of the tubes, to allow for comparison to assess the cleaning efficiency of the process. The cleaning process consisted of a high-pressure water jetting system, using a self-spinning and propelled jetting head, capable of cleaning the bores of the evaporator tubes. The scope required long periods of PVC working using specialised high pressure water jetting. All MASFE tubes were effectively cleaned, resulting in the water jetting equipment and methodology judged as successes. The Decontamination Team were able to work flexibly and provide weekend labour at very short notice, to enable the project to be completed to deadline.

KEY FACTS:

• All the MASFE tubes were successfully cleaned.

• The water jetting equipment and methodology performed well and the jetting equipment was

easily deployed

• No activity was observed in the C3 Enclosure during jetting operations

• SDS were able to work flexibly and provide non anticipated weekend working at very short notice

to enable the work to be completed