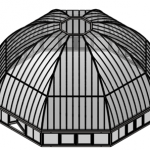

Tollcross Conservatory

Tollcross Conservatory is a B-Listed cast iron structure, also known as the Winter Gardens. Originally built in 1870, in 2010 it faced major storm damage and in 2011 was closed to the public permanently. Prior to its renovation approval, it sat on the ‘register of buildings at risk in Scotland’.

Shepley Engineers were responsible for all elements of restoration, from de-glazing, dismantling, shotblasting, painting and re-fitting. Where possible, as many pieces of existing cast iron were refurbished, however the sections that couldn’t be shotblasted and restored were fabricated and painted at the Sheffield workshop. Around 25 tonnes of new steel was used in the restoration.

The Conservatory had a timber frame which made up 60% of the structure of the building, and prior to dismantling of the timber structure Shepley undertook extensive site surveys. These surveys enabled our in-house team to design a new mild steel structure to replicate as closely as possible the original timber structure and one that would fit into and onto the two wings which were made from cast and wrought iron. All drawings were offered for final approval and around 120 drawings were produced showing fabrication details, general arrangement and interfaces

The cast and wrought iron constituted the remaining 40% of the existing structure, which was refurbished on site by Shepley’s specialist painting team. Where the remaining structure could not be salvaged the new mild steel structure was fabricated and painted off site and then fitted into and onto the remaining cast and wrought iron structure.

There was extensive workshop and site welding of each new mild steel component. Each new component or module that was fabricated off site at the Sheffield restoration workshop was built and tested in a mock-up at the workshop to ensure they fit correctly before they were sent to site. The modules were built as large as possible in the Shepley workshop to aid the site refit and were delivered to site across 8 deliveries then lifted into place using a subcontract crane team working under Shepley management.

Once the component fit was proved, and following final QA and NDT checks of both dimensional and visual aspects and compliance to the specification, the components were blast cleaned and painted to specification in Shepley’s own paint workshop.

- Shepley Engineers worked under the project specification and all fabrication works were under BSEN1090.

- All new connections were designed and approved by Shepley Engineers structural engineer subcontractor.

- Where specialist components had to be incorporated into the fabricated structures or modules then Shepley Engineers sourced and submitted control samples that were offered up and approved or commented on by the client team.

- Staged approval from the client team was sought on site for glazing as well as specialist window openers and ironmongery.